German engineering companies Dürr and GROB have developed a new concept factory for lithium-ion battery cells using less space and energy while offering higher performance and battery cell quality.

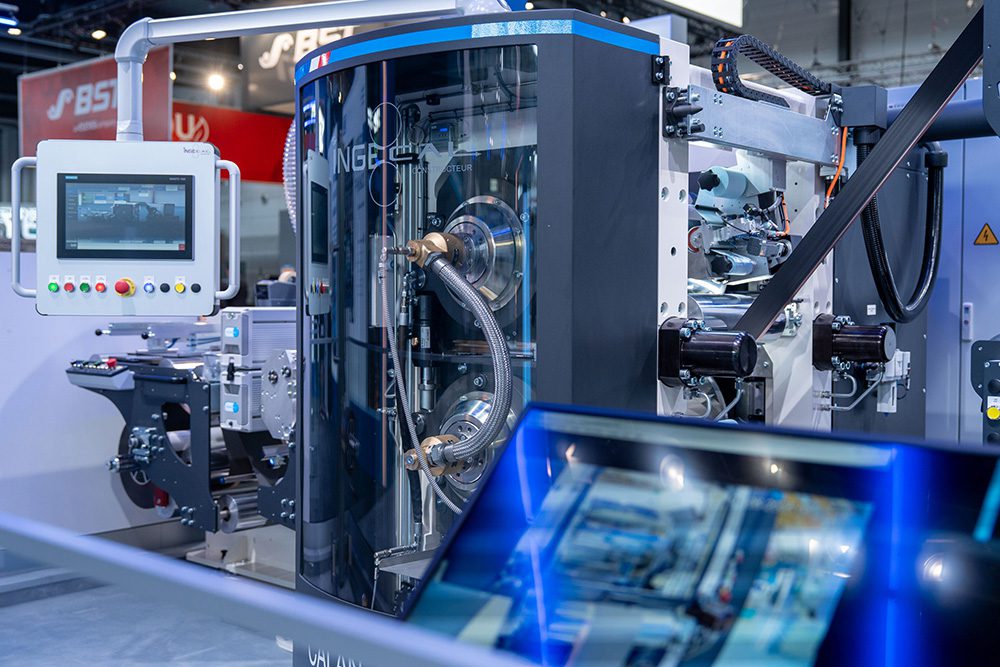

In addition to a classic production layout with wet coating, the partners have developed a concept factory that carries out dry coating of the electrodes, which does not require a drying process, and a Z-folder technology for cell assembly with integrated notching.

Instead of conventional slurry, the Activated Dry Electrode process uses a dry-mixed active material. This powder mixture is pressed into a free-standing film using calender machines, and is then laminated onto both sides of the collector foil. This eliminates the drying process as well as the recovery and treatment of solvents—saving space, energy, and costs compared to wet coating, according to the companies.

The free-standing film also offers advantages in terms of material efficiency, as excess film material can be completely returned to the production process before lamination onto the collector foil. After calendering, the coat weight can be measured directly, enabling better control of the coating thickness. The subsequent lamination onto the collector foil requires less force than calendering in the wet coating process, which means that the foil does not deform – improving its processability for downstream notching and stacking.

The new generation of Z-folders integrates the notching process. The separator is guided over a few deflection rollers with even and low web tension. A high-quality magazine buffer system for the electrodes enables the system to achieve 95% availability.

Dürr has developed a process that enables battery cells to be filled in a single step without residual gas. Unlike the conventional process, the electrolyte is filled directly into the cells at up to 30 bar. The filling pressure is two to three times higher than the current industry standard, according to the companies. The process design enables precise dosing and shortens the filling process and the subsequent penetration of the electrolyte into the active material.

The equipment technology from Dürr and GROB is complemented by end-to-end digital mapping of the production process. Dürr has also optimized the performance and energy efficiency in the classic wet coating process.

Dürr and GROB have been cooperating on production technology for lithium-ion batteries since 2022. They aim to jointly establish themselves as system suppliers of battery production equipment in Europe and North America.

“Our concept factory, and in particular the dry coating process, represents the next generation of battery cell production. Thanks to powerful and innovative technologies, production requires 50 percent less space and energy. For our customers, this means significantly higher space efficiency and lower operating costs,” said Dr. Jochen Weyrauch, CEO of Dürr.

Source: Dürr

chargedevs.com

#Charged #EVs #Dürr #GROB #present #concept #factory #battery #cell #production